How can we help drive your business?

LSR INJECTION

LSR INJECTION is a medical-grade silicone product development and medical silicone molding service original equipment manufacturer(OEM). We provide one-stop customized silicone solutions for medical device manufacturers.

For many years, we have been dedicated to the production of complex medical devices and components (Class I & Class II medical devices) in high or low volumes.

Contact us today to get the most competitive lsr molding quotation. We will be your most trusted supply chain partner.

Realize all your ideas.

LSR INJECTION’s services cover the entire life cycle from medical product ideas to product launches. With our extensive silicone rubber application expertise and medical product manufacturing experience, we can bring your concept to life faster and at a lower cost.

You can cooperate with us in the following ways.

- OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), CM (Contract Manufacturer).

- Medical silicone product development.

- Wholesale of medical silicone products.

- Silicone rubber tooling & silicone molds making.

- Manufacturable testing of silicone prototypes.

- Wholesale of high-quality medical grade silicone rubber raw materials.

WHY LSR INJECTION?

High-level design engineer team

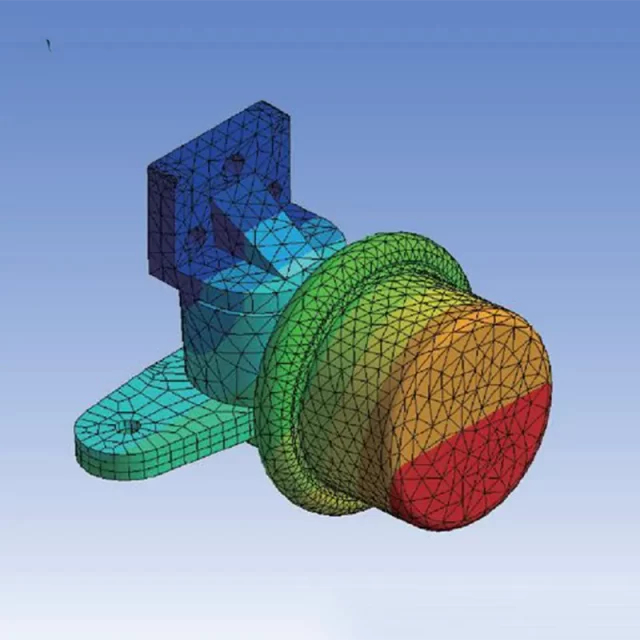

Engineering grade FEA analysis

In-house precision tooling

A wide range of materials & processes

Standardized quality system

The most competitive price

One-stop solutions

One-to-one service connection

The LSR INJECTION team will keep in close contact with you, through communication, understand your needs, and develop targeted solutions.

Permanent exclusive mold

LSR INJECTION makes unique precision metal molds for your products, you will have permanent ownership, and we will keep it safe and ready to serve you.

Complete value-added services

LSR INJECTION services include post-curing, slitting, assembly, laser marking, printing, packaging, etc. You only need to put forward your needs, we are responsible for helping you achieve.

Customizable product details

By adjusting the material formulation and manufacturing process, we can help you efficiently customize the performance, structure, appearance, and other details of the product.

Permanent exclusive mold

LSR INJECTION makes unique precision metal molds for your products, you will have permanent ownership, and we will keep it safe and ready to serve you.

Small Companies

For some enterprises with low demand for customized products, we provide corresponding cost-effective solutions. Our molded parts are available in low minimum quantities and at affordable prices to help you minimize time and cost.

Medium Enterprise

LSR INJECTION is equipped with advanced mold-making and silicone molding production lines, we can produce complex silicone parts of various materials and specifications, providing reliable and efficient manufacturing services for medium-sized enterprises.

Large Enterprise

LSR INJECTION complies with ISO and other quality compliance certifications and has independent design, manufacturing, and quality control departments. We can meet the needs of large-scale enterprises for mass parts manufacturing, and all technical parameters of the product can be customized.

Do you have a project for silicone products to discuss? Contact us today for a free quote!

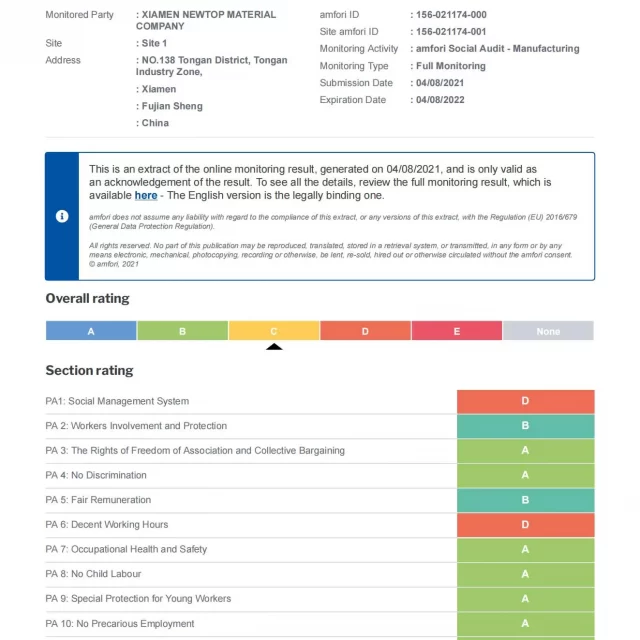

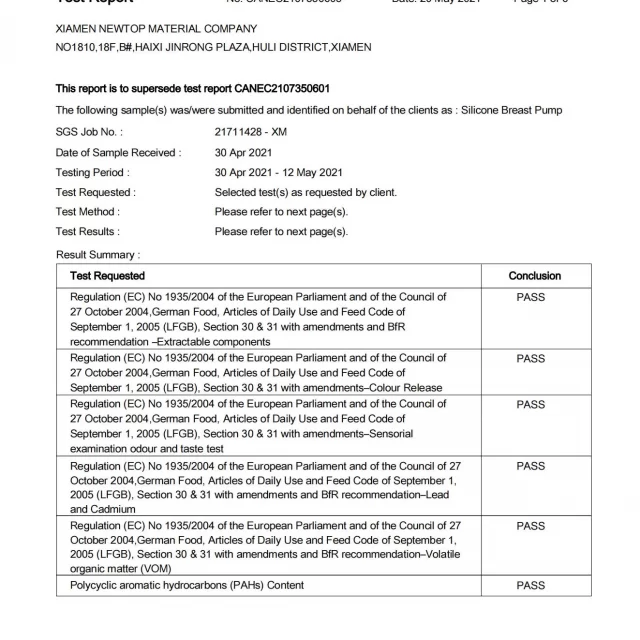

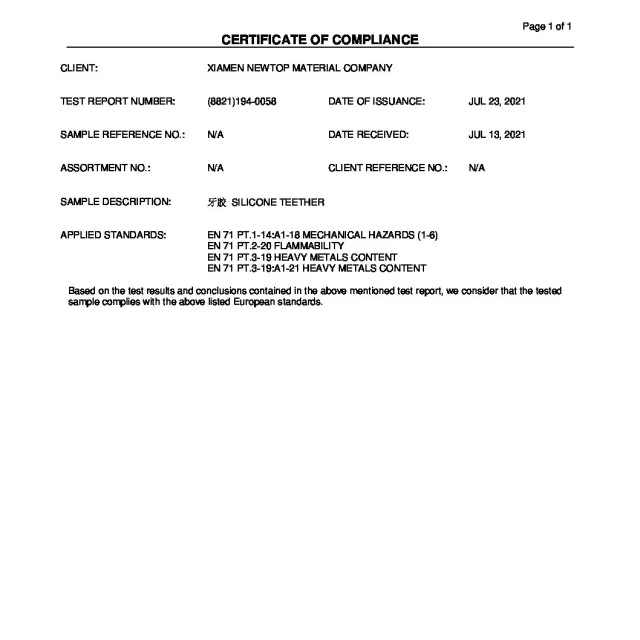

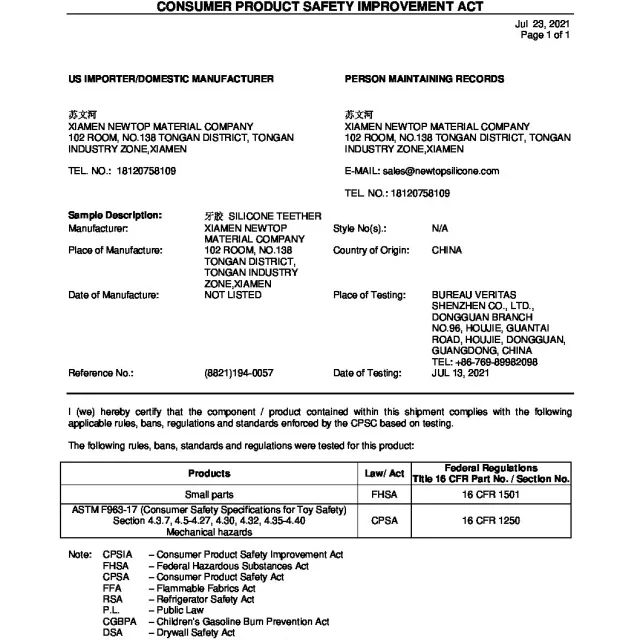

LSR INJECTION Quality Assurance

Controlled production environment

Medical parts mean tighter product tolerances and a cleaner production environment. Some medical products, such as implantable silicone rubber, require high hygienic conditions for production. LSR INJECTION Silicone factory implements strict hygiene standards. The production of all products will be in a controlled clean room environment. We can meet the needs of different customers.

Professional in-house laboratory

LSR INJECTION has its own material formulation and performance testing laboratory with professional measuring equipment to provide customers with accurate DFM+CPK reports. In addition, we can also perform the evaluation of polymer material content, elemental analysis, etc. Therefore, we can efficiently test the physical and chemical performance of products to ensure the correct ratio of silicones and additives for a specific type of product.

Product inspection & packaging

The quality inspection department of LSR INJECTION conducts meticulous quality inspections for each product. We have long-term cooperation with packaging supplies. And we can help you choose the ideal packaging option for your price range, product type, and shipping type.

Silicone Products & Molds Display

LSR INJECTION medical silicone factory’s products include medical silicone parts, CPAP masks, silicone tubes, silicone personal care products, and more.

Factory

LSR INJECTION silicone factory is equipped with a vertical liquid silicone injection molding machine, vacuum molding machine, horizontal injection molding machine, 2KM big mother Kawasaki feeder, high-speed CNC, engraving machine, mirror spark machine, 3D printer, solid flat molding vulcanizing machines, etc.

Request Quote