Silicone Tubing Manufaturing

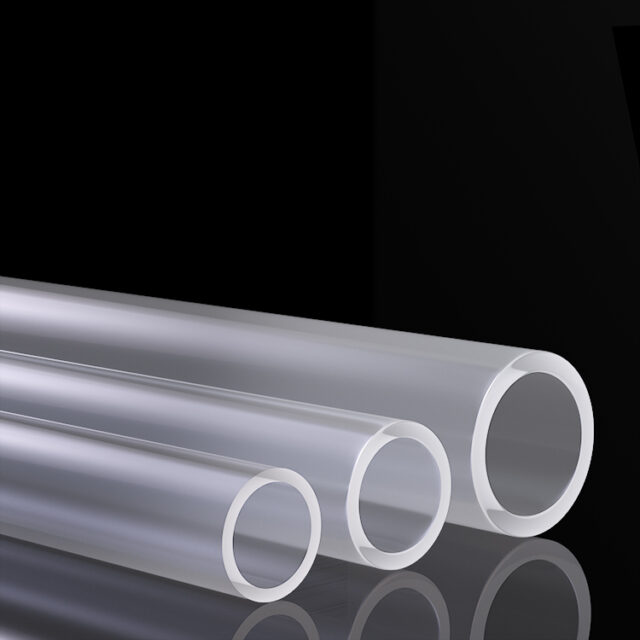

Medical Silicone Tubing

Medical silicone tubing is a thermosetting rubber elastomer with certain strength and elongation. It is based on high molecular weight linear polysiloxane, adding some specific ingredients and processing according to certain technical requirements.

Newtop Mediacla Silicone is a strong medical silicone manufacturer, we have many years of experience in ODM (Original Design Manufacturer) and OEM (Original Equipment Manufacturer) of medical silicone tubing.

We can design, prototype, mold, and mass-produce customized products. Our design service team supports personalized silicone tube customized production services and can provide reasonable suggestions and complete solutions according to your needs.

Please contact us today for more information on our capabilities or pricing.

Advantages of Medical Silicone Tubing

High transparency, high hygienic grade, non-toxic and tasteless; can withstand high-temperature disinfection and high-pressure sterilization;

Good physiological inertia, will not cause damage to human tissue, will not cause foreign body reactions after entering human tissue, and will not cause inflammation.

High tensile strength, high tear strength, low shrinkage, good resilience; good hydrophobicity, breathability, and light transmission.

It has strong high and low-temperature resistance, and will not deform or decompose harmful substances at high temperatures.

Application of Medical Silicone Tubing

It is mainly used as a clinical medical accessory. Specifically, it can be used in drug diversion, biopharmaceuticals, medical analysis instruments, ventilators, and medical research.

In addition, this grade of silicone tubing is also suitable for food and beverage transmission, food and beverage transmission, peristaltic pumps, veterinary drugs, pharmaceuticals, and other chemical fields.

High-Level Silicone Tube Manufacturing Services

NEWTOP Medical Silicone uses high-quality gas-phase liquid silica gel as raw material and is instantly vulcanized by a two-component (A/B) addition vulcanizing agent. At the same time, a high room temperature vulcanizing agent is used to assist in curing, which makes the vulcanization speed significantly improve. Compared with traditional peroxides Compared with the vulcanization process, our silicone tube has better biocompatibility and better light transmittance.

NEWTOP is equipped with multiple high-speed silicone extrusion molding production lines and large-scale digital cutting machine tools. So we can provide you with low-cost, high-precision medical silicone tube custom manufacturing services in a high-precision and low-cost way.

NEWTOP has a complete management system. We strictly control the entire production process. All batches of products are subject to quality testing and batch sample retention procedures to ensure that our products meet the highest quality standards and that raw materials are fully traceable.

Our Products have passed food-grade safety testing such as FDA and LFGB.

A Broad Range of Standards

- Temperature Range: Silicone tubing can withstand temperatures from -130°F to 600°F.

- Hardness range: 20 Shore A to 90 Shore A.

- Pressure resistance: 8mPa

- Color Availability: Supports custom colors.

- Specifications: Supports manufacture in various calibers and lengths.

- Material: Support medical-grade liquid silicone and platinum curing.

- Process: silicone extrusion molding, silicone injection molding, etc.