Want to make high-quality medical silicone parts at the lowest price?

- The best silicone manufacturer in China

- The most competitive prices you can find

- Experienced team of designers & engineers

- Next-generation silicone molding technology

- One-stop private customized solutions

- ISO-certified factory to ensure quality

- Easy to reach MOQ

Realize all your ideas

LSR INJECTION is a medical silicone parts original equipment manufacturer ( OEM ) and silicone products (Class I and Class II medical devices) manufacturing company.

Capabilities Include:

- High-precision cold runner

- Precise color paste control

- 3D printing technology

- Liquid silicone micro-injection molding technology

- Liquid silicone overmolding technology

- Flash-free liquid silicone mold design and processing capabilities

Cooperation Method:

- OEM, ODM, CM

- Medical silicone product(parts) development.

- Wholesale of medical silicone products.

- Silicone rubber tooling. & silicone molds making.

- Manufacturable testing of silicone prototypes.

- Wholesale of high-quality silicone rubber raw materials.

WHY LSR INJECTION?

Product Development Consultant

- CAD digital model building

- Manufacturability assessment

- Prototype performance testing

- Private customized solution

Fast Molding & Turnaround

- Injection Molding ( including multi-shot )

- Extrusion Molding

- Compression Molding

- Overmolding

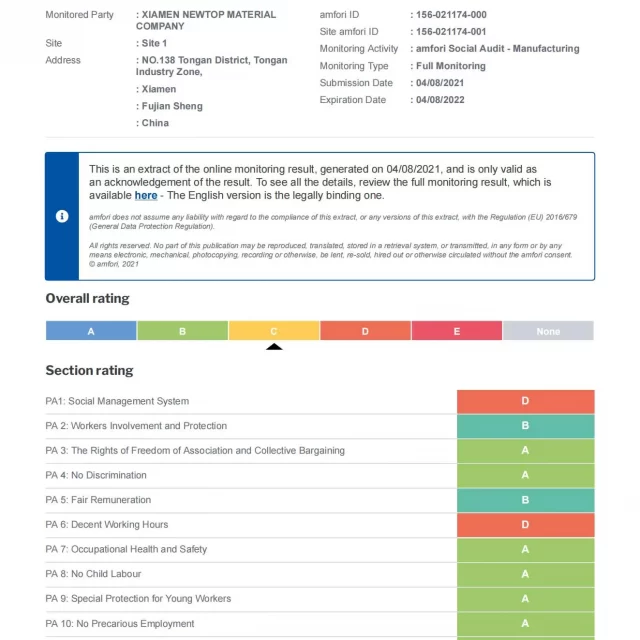

Standardized Quality System

- ISO 9001:2015 certified & manufactured to ISO 13485:2016.

- Customizable specifications, precision, tolerances, etc.

Controlled Production Environment

- Supports controlled environment (Class 7 clean room) molding needs.

Value-added services

- Complete value-added services, including post-curing, slitting, assembly, laser marking, printing, packaging, etc.

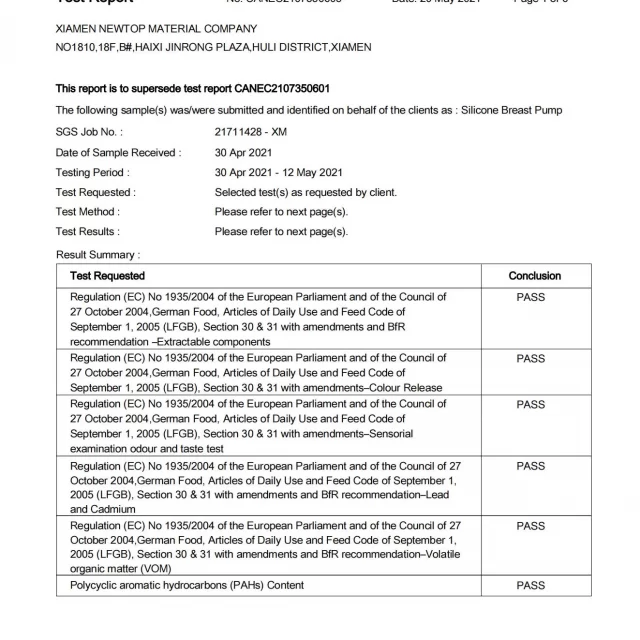

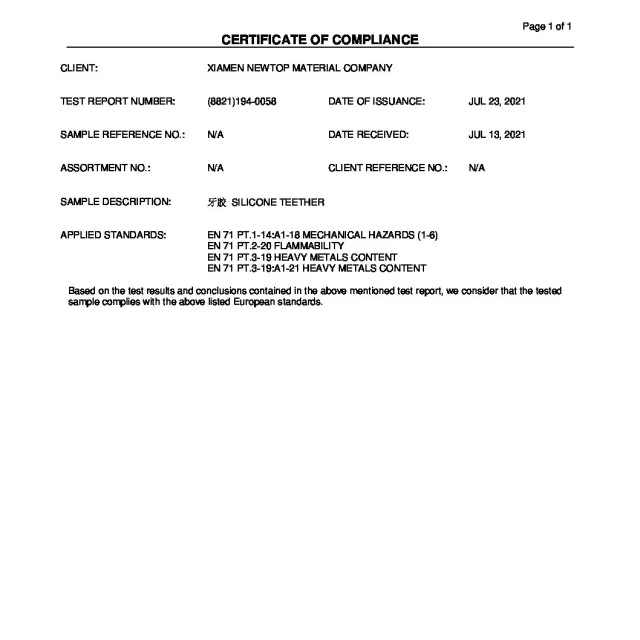

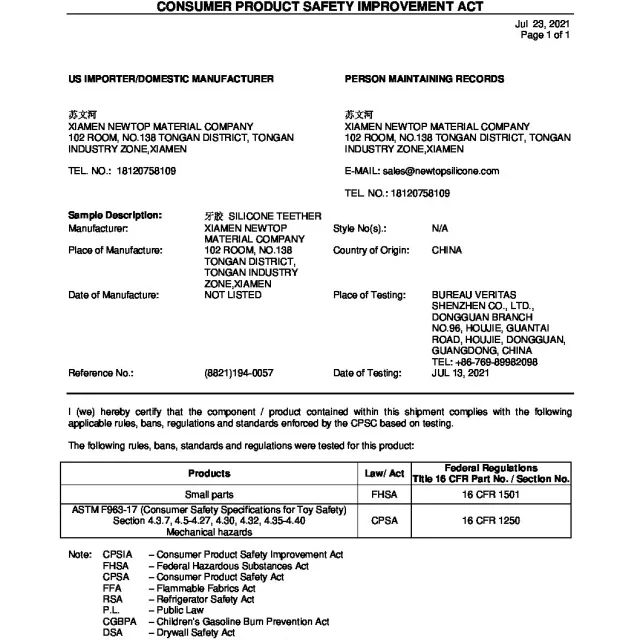

Medical Grade LSR

- Non-phthalate

- Latex free

- Gamma and EtO Stable

- ROHS compliant

- Anti-microbial

- DEHP-free

Do you have a project for silicone products to discuss? Contact us today for a free quote!

One-Stop Medical Silicone Parts Molding Service

Customer-first is our consistent principle. Our services cover the entire life cycle from medical product ideas to product launches. At LSR INJECTION, you can get one-on-one personalized customization services, including exclusive project quotes, manufacturability assessments, guidance on production material and process selection, manufacturing tracking, post-processing, and more.

We manufacture complex medical devices and components with the utmost enthusiasm for both small and high-volume needs. With our extensive silicone rubber expertise and medical product manufacturing experience, we can bring your product to market faster and at a lower cost.

Precision Medical Silicone Parts From China

Medical parts mean tighter product tolerances and a cleaner production environment. This is exactly what LSR INJECTION is doing. We use high-quality medical grade LSR (Liquid Silicone Rubber) as raw material, combined with next-generation manufacturing technology, to manufacture products in a strictly controlled clean room environment.

As one of the leading forces in the manufacturing of silicone medical devices in China, LSR INJECTION has the most mature internal processes and a complete QA system. Through in-house mold making workshops, CNC and EDM tools, and digital multi-shot injection molding processes, we can meet almost all grades of precision requirements of our customers.

LSR INJECTION is ready for any business at scale

Small Companies

For some enterprises with low demand for customized products, we provide corresponding cost-effective solutions. Our molded parts are available in low minimum quantities and at affordable prices to help you minimize time and cost.

Medium Enterprise

LSR INJECTION is equipped with advanced mold-making and silicone molding production lines, we can produce complex silicone parts of various materials and specifications, providing reliable and efficient manufacturing services for medium-sized enterprises.

Large Enterprise

LSR INJECTION complies with ISO and other quality compliance certifications and has independent design, manufacturing, and quality control departments. We can meet the needs of large-scale enterprises for mass parts manufacturing, and all technical parameters of the product can be customized.

Request Quote