Quality System

Newtop Silicone has been highly acclaimed over the years as an important LSR product supplier to hundreds of well-known companies around the world. This is due to our precise control of quality. From the product design stage, our quality service runs through. Each of our production processes has corresponding quality inspection procedures, and these procedures are updated at any time to adapt to changes in production.

After our team receives your needs, we will give you feedback within 24 hours at the latest, and maintain necessary communication and cooperation with you at all times. This helps us understand your expectations for product features and production cycles. Establishing efficient and close contact with customers is an important part of our service quality system.

Newtop Silicone constrains our production process with stricter self-standards under the industry’s common production standards. First of all, we use a large number of automated production equipment and standardized production procedures that have been scientifically proven. In addition, our workers are trained in professional vision training and manufacturing methods. So we have been able to improve the quality of our products to an excellent level that far exceeds the requirements of our customers.

In the production process of Newtop Silicone, one thing that has to be mentioned is our precise measurement of product dimensions. We use lab-grade metrology equipment and even have custom fixtures designed for certain types of products, such as automotive silicone parts. We believe that dimensional accuracy is one of the factors that reflects the standardization of products and the strength of the factory, so we control the probability of errors in it very strictly.

Many silicone products with strict usage scenarios cannot be produced outside the clean room. The Newtop Silicone Silicone Rubber Factory provides our customers with a high standard Class 8 clean room solution. Cleanrooms improve product quality by minimizing contaminants that may occur in the production environment.

Newtop Silicone also attaches great importance to the performance of the product. The quality of the product depends largely on whether its functions meet the requirements. Newtop Silicone tests product performance by simulating specific usage scenarios. We minimize all possible usage conditions and unexpected situations. In addition, Shore hardness and tensile testing are also included in our product quality testing segment.

Newtop Silicone has stable cooperation with a number of internationally renowned large-scale silicone rubber raw material suppliers. Only materials that meet the standards will be allowed into the workshop. Therefore, we guarantee that the quality of silicone rubber raw materials is superior. The raw materials of each product that leaves the factory are traceable and queried.

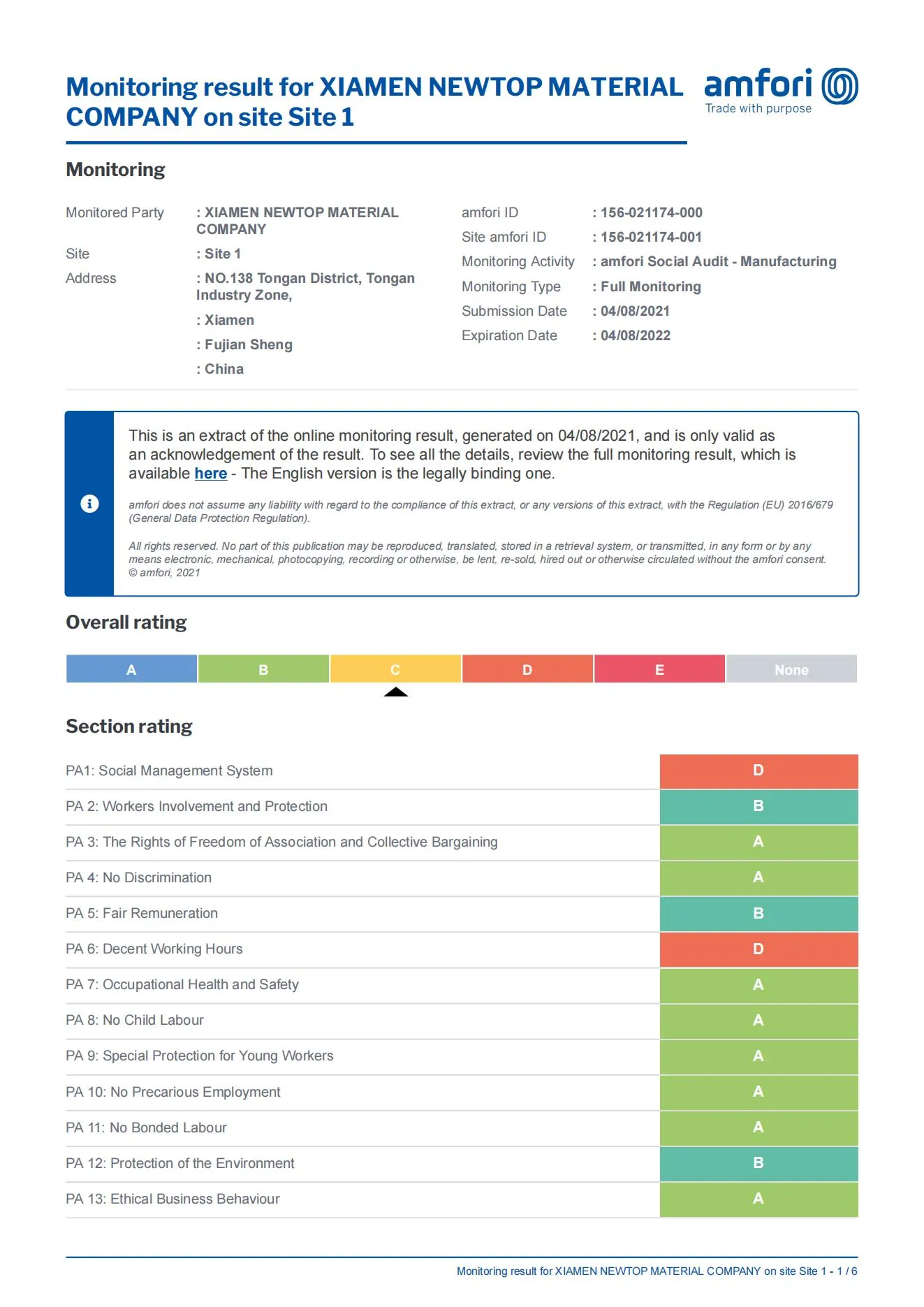

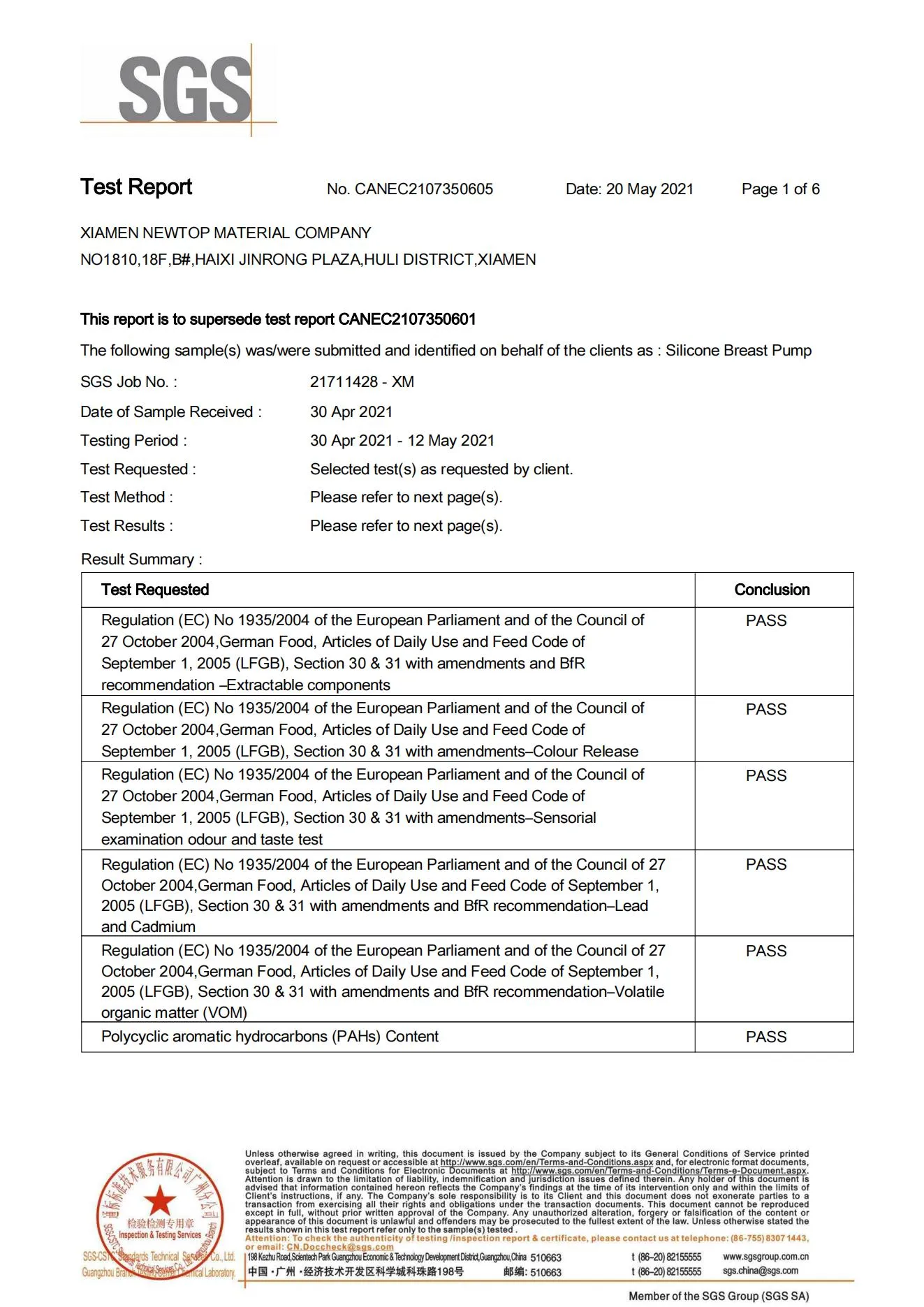

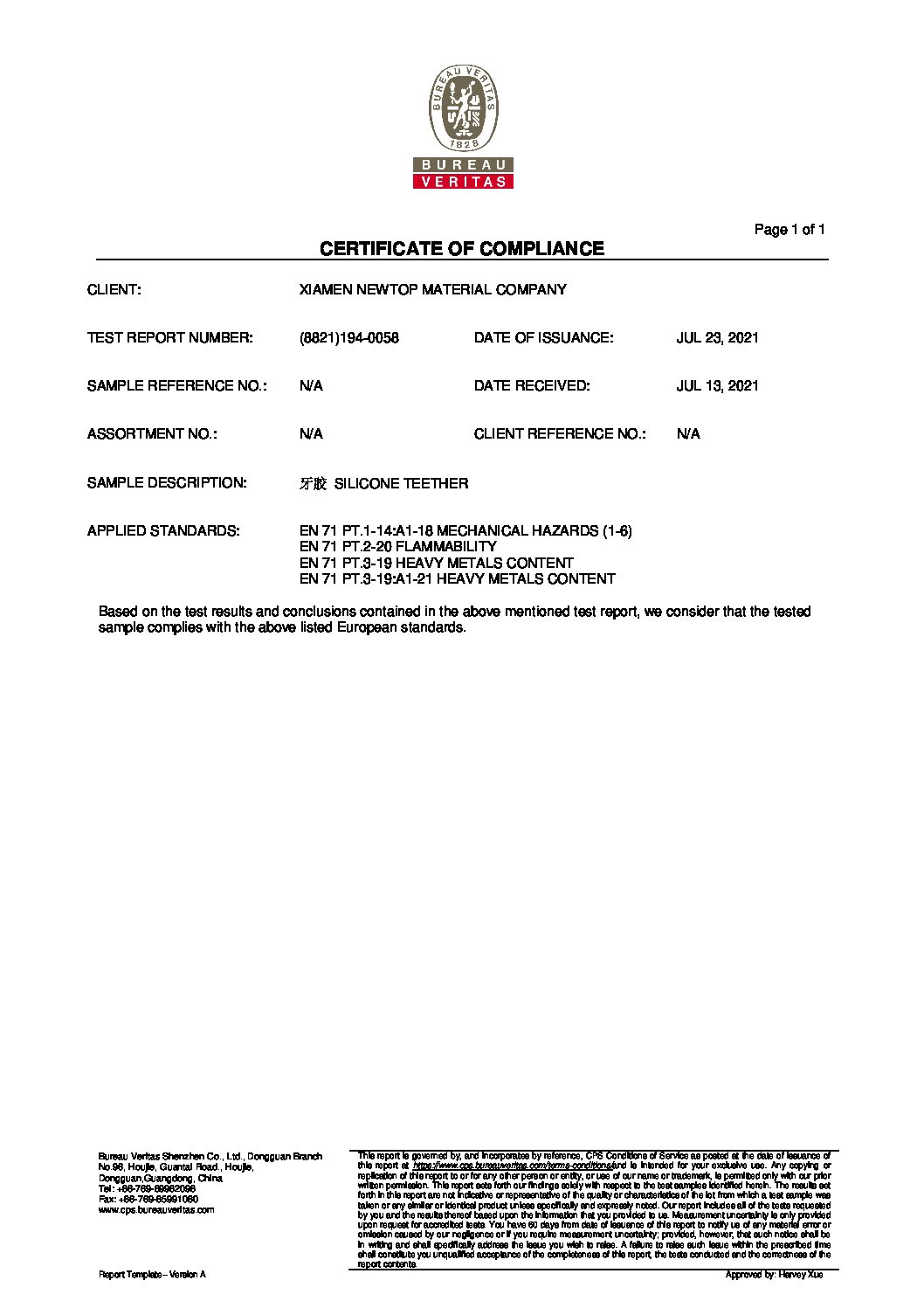

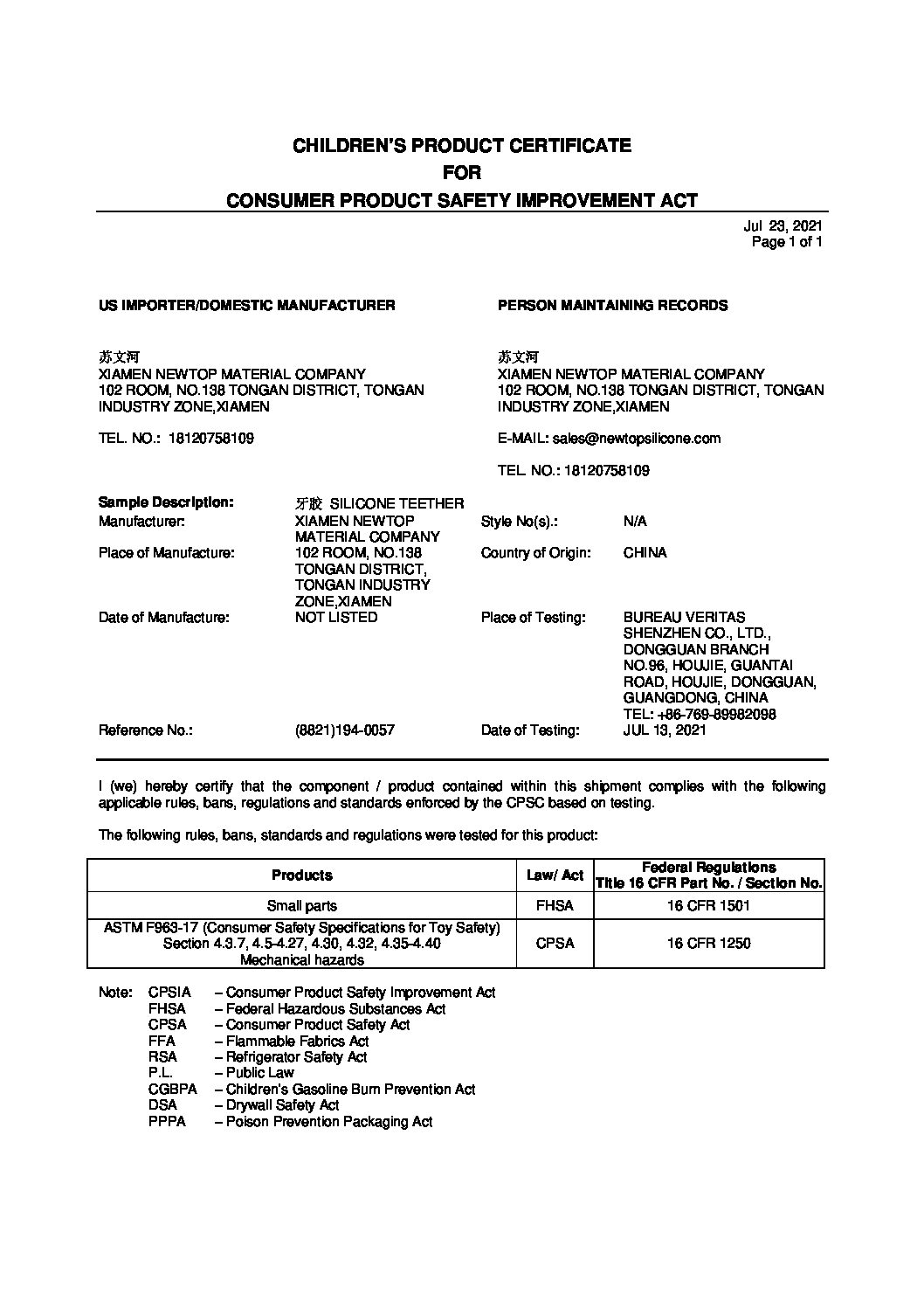

Newtop Silicone can meet the third-party quality standards required by many customers, such as FDA, CE, CPC.COC, ISO,SGS certification. And we’ve proudly maintained these quality certifications over the years.

Newtop Silicone part of the certificate display

Start a New Quote