Silicone Prototyping

Silicone Prototyping

Most customers are reluctant to use hard production tools without prototype parts to verify that their designs will perform as expected and get commercial feedback in the market. So we provide our customers with silicone prototyping as a pre-test product performance channel.

LSR INJECTION’s medical silicone prototypes process includes complete silicone product evaluation, custom mold design and fabrication, and prototype component manufacturing.

By manufacturing prototypes, we can help you effectively reduce project costs, eliminate complexity, improve mass production quality, and avoid possible risks.

Rapid Prototyping Service

Reliable FEA Analysis and Evaluation

Multiple options for silicone prototyping

Wide range of silicone materials

Supports flexibly modifiable prototypes

Design for Manufacturability

Material

Different materials endow medical silicone products with different properties to suit the needs of various application scenarios. LSR INJECTION prototype engineers will select some possible silicone materials to manufacture prototypes according to specific situations, and test its properties to determine Which is best for producing your product.

We specifically offer a wide range of optional materials and additives to bring more possibilities to your products.

- Liquid Silicone Rubber (LSR)

- High Consistency Rubber (HCR)

- Room temperature vulcanized rubber (RTV)

- Colorant

- Vulcanizing agent

- Other

Design

For medical silicone products, there is no best design, only the most suitable design. We will ensure a smooth communication mechanism with you, and actively negotiate to identify and solve various design problems.

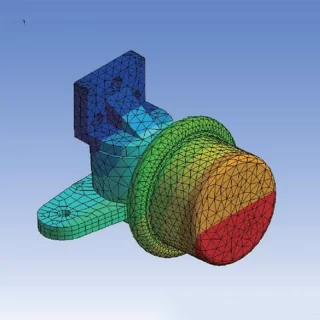

LSR INJECTION’s experienced engineering designers use CAD tools and FEA to build digital models of products and optimize structural designs to make them more visible and assessable.

By improving the manufacturing process during the design and prototype testing stages, we can find the balance of the design, saving unnecessary and expensive product revisions for subsequent processes.

Prototype Manufacturing Method

3D Silicone Printing

3D silicone printing is an advanced manufacturing technology. Its principle is to construct objects by layer-by-layer printing through the principle of additive.

While you can hardly expect it to bring you significant cost benefits, the technology has significant advantages in the rapid prototyping of products with particularly complex geometries and structures.

Soft Tooling & Injection Molding

Soft tooling generally uses molds made of soft steel such as NAK80. Its structure is relatively simple, the mold hardening process is omitted, no heat treatment is required, and it can be directly machined and then put into use. This kind of mold can usually be combined with the injection molding process for molding.

The advantage is that the unit price is cheap and the manufacturing cycle is short. For quick soft tooling, we can usually be 30-50% cheaper than full production tooling and 40-60% less lead time compared to traditional tooling. It is very suitable for the development of prototype manufacturing-related processes such as structure and test identification of products, identification of product performance, and confirmation of appearance and data.

Compression Molding

Using an aluminum single-cavity compression mold is one of the most cost-effective ways of prototyping. It usually takes 1-2 weeks to manufacture, depending on the complexity of the prototype required. It supports limited modifications and is ready to use mass-produced at a certain scale.

Compression molding molds are more durable than soft molds, and many customers who have little demand for products tend to choose this prototype method.

RTV Casting

RTV (room temperature vulcanization) is a mature, manual prototyping process that saves you the most on prototyping costs.

You can use it to turn a digital model of a CAD drawing into a real-life prototype. But we think of it more as a visual demonstration product than something worth testing its functionality.

Do you have a project for silicone products to discuss? Contact us today for a free quote!

Ready to make a prototype?

With LSR INJECTION’s medical silicone rapid prototyping. We can easily build a physical model of the product. It reflects the most realistic performance and specifications of the product. Whether it is simple or complex silicone parts and silicone products, this link should be passed to verify the manufacturability of the product before mass production.

Our professional team of engineers will optimize the entire process with the following considerations.

- Mold Machining

- Cost & Lead Time

- Tolerances for Silicone Parts

- Surface Finish

Our molds deliver high levels of productivity and durability. We use CNC (Computer numerical control) machines and EDM (Electric discharge machining) machines to cut metal molds for prototyping. This specialized mold can run almost any type of silicone rubber material. In addition, the mold supports minor modifications.

Mold manufacturing will be completed within 3-7 working days, and prototype production can reach mass production standards within 7-10 days. Cost depends on the complexity of the silicone product and material selection.

We control the production in full compliance with the Rubber Manufacturers Association’s production tool tolerance standards, grades A1-A4, which stand for high precision, precision, commercial, and basic, respectively.

We can achieve a highly polished surface, or a matte finish, depending on the customer’s needs.

LSR INJECTION Silicone Prototype Solutions

Since 2009, LSR INJECTION has been specializing in the design and manufacture of medical silicone rubber products with a global reach.

Our products include silicone medical accessories and Class I/II medical devices containing silicone. Over the years, we have continuously expanded and upgraded our production capacity to provide customers with sustainable quality products and services.

As one of the largest silicone manufacturers in China, LSR INJECTION has accumulated years of experience in silicone rubber production. We have a complete engineering and design support system, low-cost production tools and a fast turnaround guarantee. Moreover, you can enjoy exclusive customized solutions and the most competitive prices.

Time is money, you need a strong silicone manufacturer you can trust, and we’re a partner that can give you a significant advantage. Contact us and let us help you bring your product to market.

Start a New Quote

Silicone Prototype Related Content

ODM Silicone & OEM Silicone

ODM & OEM service starts with customized requirements and effective communication. Our sales and engineer team will keep close contact with customers by email, phone, etc. What you need to provide is the name of the product, the idea of the function, or the specific drawings and samples.

During the product design phase, our job is to give you reasonable advice based on your needs and help you build a clear view of the product and process. Designers use CAD (computer-aided design) tools to convert product ideas in your mind into digital models on the computer, which is the best way to visualize product details.

Silicone Product Development

Mold simulation technology alone is not enough, we will also combine decades of production experience to optimize the manufacturing design of silicone products. This includes materials, processes, specifications, appearance, and more.

It makes more sense to choose the right material than to choose an expensive material that is not really needed. The silicone elastomers we provide include HCR (High consistency silicone rubber compounds) & LSR (liquid silicone rubber).

Materials & Technology

HCR is a kind of heat-cured rubber, and some areas call it solid silicone rubber. We usually recommend customers use this material in industrial fields, especially for automotive silicone parts and electronic silicone parts. Because of its excellent mechanical properties and insulating properties, it can withstand long-term extreme environments. We produce it using a proven compression molding process. By applying high pressure inside the mold, the HCR raw material is thermally cured into a stable product in the shape required by the customer.

LSR is non-toxic and odorless silicone rubber. The biggest advantage of this material is its high biocompatibility, which means it is absolutely safe for humans and the environment. It is often the first choice for customers related to household products such as baby products and kitchenware. The processing method of liquid silicone rubber is mainly liquid injection molding technology, including general silicone injection molding, overmolding, multi-shot injection molding, etc. We will evaluate which process is suitable for the processing of products using such materials according to the complexity and characteristics of the products required by customers.