LSR Multi-Shot Injection Molding

Multi-Shot Injection Molding

Liquid silicone rubber multi-shot injection molding, also known as LSR Multi-component injection molding, is one of Multi-material injection molding. This is a process of molding several different materials in one mold, and it is significantly cost-effective.

The difference from injection molding is that this process requires an additional injection unit (separate nozzle) and an additional mold for the corresponding material. They range in number from 2 to 6 and are used to fill different materials mixed with different colorants. This is very suitable for the combined molding of materials of different shapes.

In the multi-shot liquid silicone rubber injection molding process, materials at temperatures around the melting point are injected into the mold cavity in a specific sequence. After the first shot is finished and cooled, the machine automatically transfers the material into the second mold, which closes. At this point, the most critical reaction begins, delamination occurs between the materials, but the chemical bond between them will be very tight, which has a higher bond strength than overmolding or insert molding. Next, another material is injected into the mold, and after solidification is completed and cooled, it is transferred to the next mold for molding until the required number of times is completed.

The precision multi-shot silicone rubber injection molding process is usually supplemented by finishing, which includes assembly, trimming, etc.

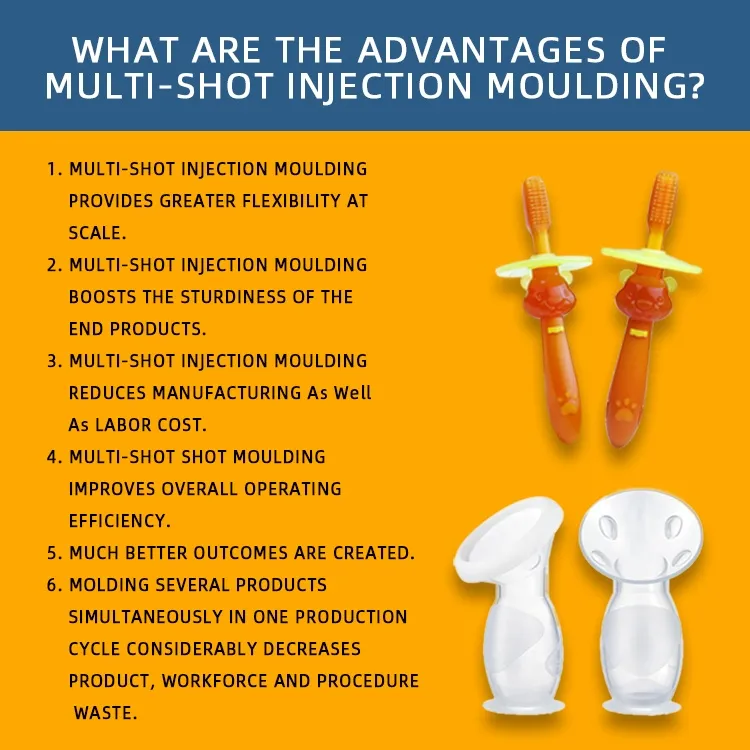

Advantages of Multi-Shot Injection Molding

Higher production efficiency. A variety of materials are produced in one process, which reduces the number of processes and effectively reduces the production cycle.

higher quality. Multi-shot injection molding products have higher precision, lower tolerances, and less defective rates.

Multi-Shot Injection Molding is a process through which you have multiple materials injected into the mold at the same time. It’s more complex than a single injection, but it also conveys a lot more value and benefits to the process. It’s easier to do, it gets the job done very well, and it pushes the boundaries to bring in a very good and engaging experience every time. Plus, it also represents the latest tech in the world of liquid silicone rubber injection and it comes with a vast range of advantages too.

During the Multi-Shot Injection Molding process you will have the integration of thermoplastic, metal and LSR into a single component. Then the injections are applied with the use of different nozzles at different surface locations. What this does is it provides you with a great way to produce pretty much any type of small or even larger automotive components. You can do handles, hinges and a variety of moving parts too. All of these can be fully implemented and customized the way you want, with little to no restrictions.

Newtop Silicone is committed to turning your brilliant ideas into reality, providing you with all silicone design and production services. Through Newtop Silicone’s highly automated multi-shot injection molding technology, we enable the efficient production of complex precision components.

Start a New Quote